ONLY now, three years after Akio Toyoda launched TNGA – Toyota New Global Architecture – do we really understand the complexity and cost benefits of what is a multi-architecture strategy.

First perceptions suggested TNGA was one highly adaptable architecture, suitable for use for small and large vehicles – and everything in between – and capable of supporting front, rear and all-wheel drive layouts.

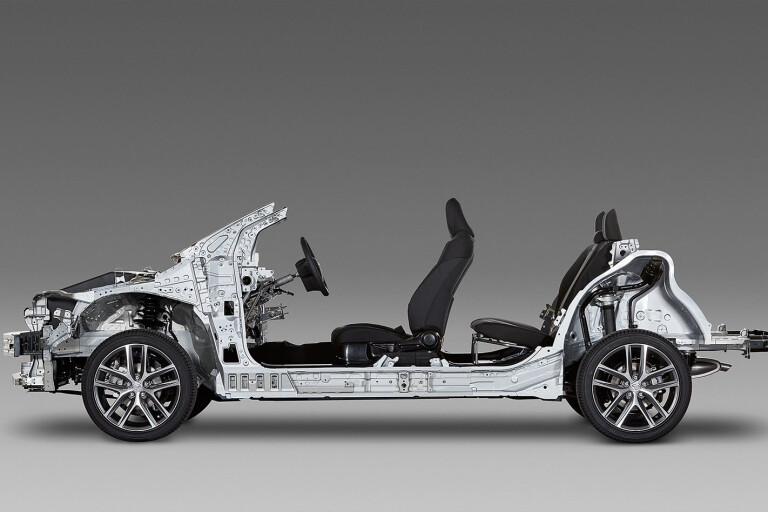

Instead, TNGA is four entire separate platforms. Effectively, Toyota is now split into four separate business units, each sustaining its own architecture. What they share is the same engineering and design philosophy: “lower centre of gravity, attractive low-stance designs, responsive handling, a high-quality drive feel, and collision performance that offers safety and peace of mind”.

RAV4 chief engineer Yoshikazu Saeki’s business card reveals the true complexity of the system: “Chief Engineer ZD, MS Product planning, Mid-size Vehicle Company”.

Only by breaking down this Toyota-speak can we begin to appreciate what TNGA sets out to achieve. Z indicates Product Planning; D the specific architecture; MS mid-sized products.

According to Saeki, the business units are: ZE - compact models like the Corolla, C-HR and Prius and their variants. ZD - comprises sedans, SUVs and MPVs: RAV4, the next Kluger (Highlander in the USA) and Sienna, and the Japanese Harrier, plus Camry, Avalon and the Lexus ES. The next generation Yaris and other small, mostly Japan-only, models are expected to be built on the new ZB architecture, while body-on-frame Commercials, like the LandCruiser, Prado 4Runner and Sequoia, are designated CV.

To further complicate the naming classifications each business group uses TNGA followed by a letter that indicates the architecture. ZD becomes TNGA-K; while TNGA-C is Corolla and Prius; Yaris is predicted to be TNGA-B.

Toyota chairman Akio Toyoda says Toyota’s aim is to reduce development costs of any new model by around 50 percent compared with 2008 levels. He wants to ensure that Toyota remains among the top car makers, not only in terms of volume but profitability, too.

Saeki says the major cost saving comes through the sharing of the most important engineering ‘hardpoints’: the engine compartment, on an architecture by architecture basis. The engine compartment includes the front crash structure and firewall, and the width of the side body frames are essentially identical for all TNGA-K models. According to Saeki, what changes from one architecture to the others is the width of the engine compartment. Otherwise, wherever possible they share the same steering rack and electric power steering and front MacPherson strut suspension, both tuned to best suit each particular model.

Using Camry as the starting point for all TNGA-K models, creating what Toyota calls a “progressive data base”, allows the engineers to accurately forecast the entire crash structure for future models.

“Crash testing takes the longest,” says Saeki. “For Camry we had to make prototypes and crash them. From this data we can get stimulation to forecast the crash data for all the other (TNGA-K) models.

“For the RAV4 the body structure – the longitudinal side beams – rear of the engine compartment is raised (compared to Camry) to increase ground clearance”. The benefits “allows us to focus on the upper body and our aggressive design.”

However, if needed, there are significant differences in the rear suspensions of the Camry and RAV4. Where the Camry adopts double wishbones, the soft-roader gets a so-far unique trailing wishbone, multi-link rear suspension that better copes with different weight transfers.

“We are in the middle of the process (of changeover), says Saeki, “it might look complicated, but the new Highlander (Kluger) is like a big RAV4. The RAV4 is the entry (SUV) offering and the Highlander is an upgraded version. The saving is in the budget, rather than in time.”

For the RAV4, Toyota shortened the Camry’s 2825mm wheelbase by 135mm to 2690mm. “It’s possible to go more (than Camry),” says Saeki, “Rather than that, the rigidity of the side (body) components is the limiting factor. It’s possible we need to add strengthening.”

“The Highlander is longer (in wheelbase) than the Camry and, with the RAV4, sets the coverage range (of TNGA-K).

Do the new architectures bring weight savings? Not according to Saeki, who blames coping with recent changes to crash regulations and coping with future crash regulations. “It’s a constant struggle with the changing regs, so there is no given weight reduction.”

Will the next Kluger follow the trend to smaller capacity engines? Apparently not. The current model is available in V6 and, in the USA, as a hybrid. Expect Australia to pick-up both versions when the new model goes on sale in late 2019 or 2020.

What of electric plug-in versions of TNGA-K?

“Plug-in is easy to do,” claims Saeki. “But it is expensive and we have to give maximum value. Price is the big factor.”

Two high-profile Toyota models are not integrated into TNGA. Both jointly developed with other manufacturers: the 2012 86 was a part of a project with Subaru – because it retains its Subaru-boxer engine it’s believed the replacement model comes from the same blueprint – and the new Supra, a co-operative development with BMW.

Our conclusions: a better appreciation of the TNGA confirms that it is far closer in philosophy and practice to the VW Group’s MQB, MLB, MHB and the new MEB architectures than originally believed. On the evidence of the Corolla, Camry and RAV4 TNGA is quickly changing our perception of Toyota. No more boring cars.

COMMENTS